Technical Advantages

With nearly twenty years of professional manufacturing experience, we have accumulated deep technical strength and innovation capabilities in the field of high-voltage power components

Why Shield Rings Are Needed

With nearly two decades of professional manufacturing experience, we have accumulated deep technical strength and innovation capabilities in the field of high-voltage power components

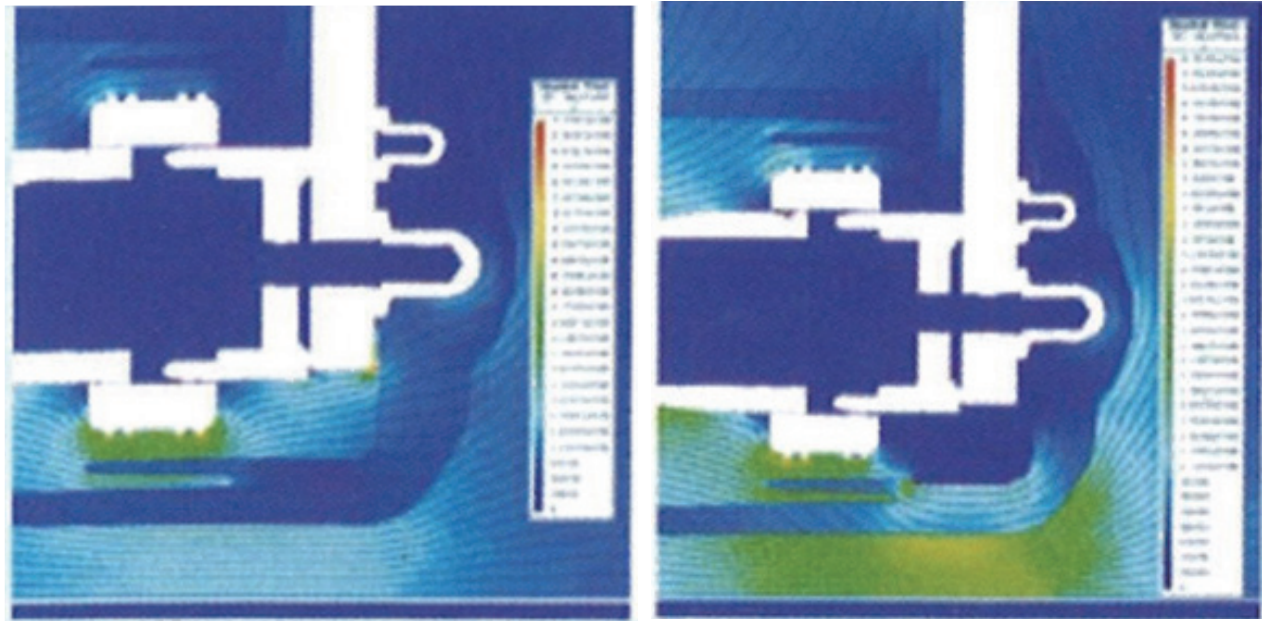

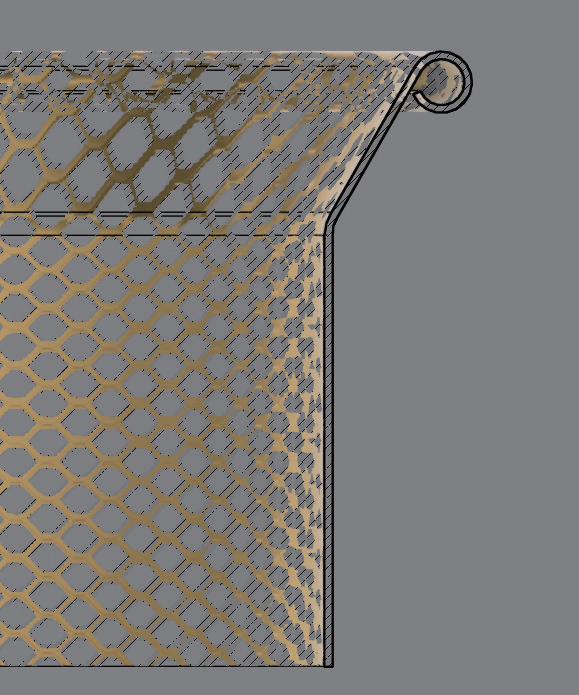

Contact Box Electric Field Simulation Analysis

Figure 1 shows the electric field simulation results of contact boxes used in medium voltage switchgear: In the upper diagram without shield rings, the maximum value appears in the gap between the busbar corner and the contact box. In the lower diagram with shield rings added at the root of the contact box, the electric field between the busbar and contact box gap is effectively reduced.

Technical Advantage:Through the application of shield rings, the electric field strength is significantly reduced, improving the insulation reliability and service life of the equipment.

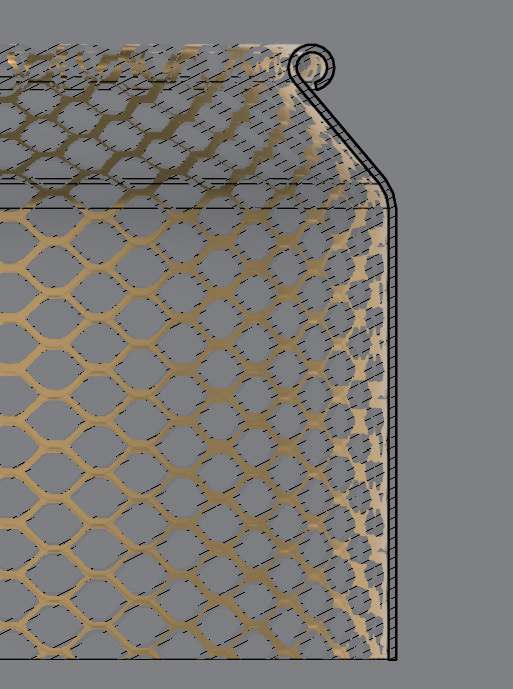

Wall Bushing Electric Field Optimization

Figure 2 shows the electric field simulation results of wall bushings used in medium voltage switchgear: In the left diagram without shield rings, the maximum values are distributed in the gaps between the wall bushing and mounting plate, and in the air gaps between the busbar and wall bushing. In the right diagram with high-voltage and low-voltage shield rings added to the wall bushing, connected to high voltage and ground respectively, the electric field between the busbar and wall bushing gap is effectively reduced.

Certification Achievement:This component, combined with the switchgear, passed the type test at Xi'an High Voltage Electrical Research Institute in one go, improving the insulation reliability and lifespan of the product.

Shield Ring Materials

Multiple material options to meet performance requirements for different application scenarios

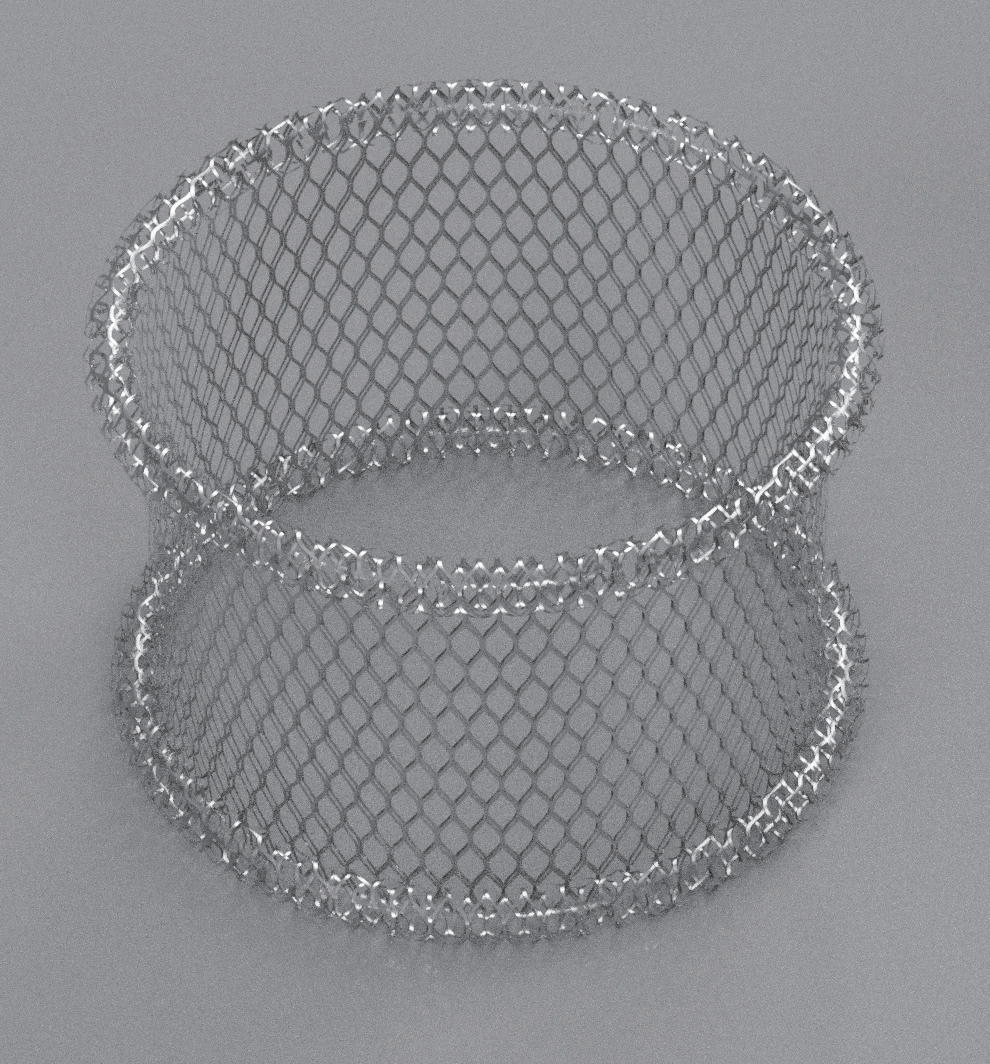

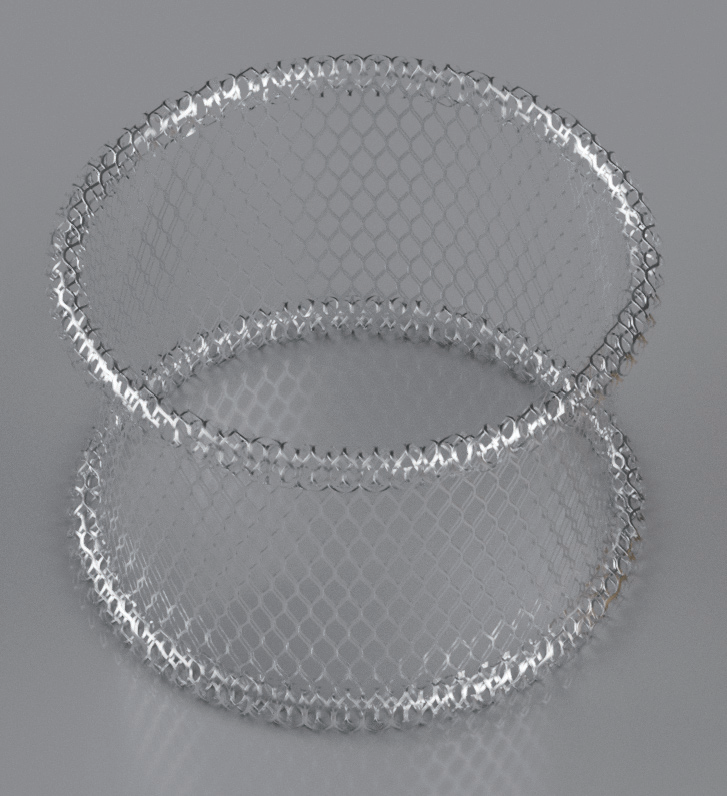

Stainless Steel SUS

Commonly used materials include AISI 201, AISI 304, and AISI 316, with AISI 304 being the standard choice. It offers good corrosion resistance, heat resistance, and machinability at a lower cost. When made into shielding nets, it has good strength and hardness, and is less prone to secondary deformation during transportation.

Technical Features:

- Excellent Corrosion Resistance

- Good Heat Resistance and Machinability

- High Strength and Hardness

- Stable During Transportation

- Excellent Cost Effectiveness

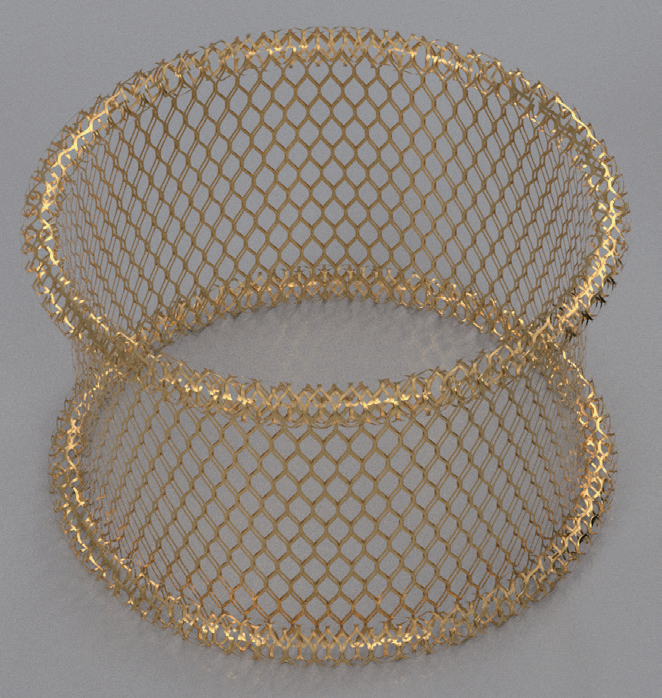

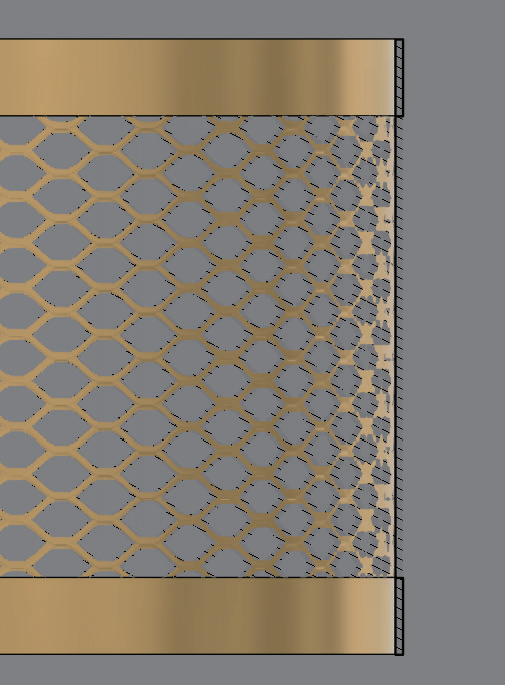

Brass BRASS

Mainly H62 and H65 grades, each with advantages in hardness (shape retention) and ductility. Both processing and material costs are higher than stainless steel. Due to better ductility, it produces fewer micro-burrs during complex shape forming compared to stainless steel, and has better partial discharge performance under certain conditions.

Technical Features:

- H62/H65 Specifications Available

- Excellent Ductility

- Fewer Burrs in Complex Forming

- Better Partial Discharge Performance

- Strong Precision Machining Adaptability

Aluminum

Aluminum mesh has the best ductility and lightweight properties, with a thermal expansion coefficient closer to epoxy resin than brass and stainless steel, while maintaining good electrical conductivity. However, its main disadvantage is that the material is too soft, and when inserts are fixed to the mesh, it often destroys the original shape of the mesh, causing secondary deformation.

Technical Features:

- Best Ductility and Lightweight Properties

- Thermal Expansion Coefficient Close to Epoxy Resin

- Good Electrical Conductivity

- Soft Material Requires Special Treatment

- Made from 1000 Series Pure Aluminum

Nylon NYLON

Material uses PA66+30CF, an organic polymer material with good affinity to epoxy resin. After sandblasting, it bonds better with resin. Contains 30% carbon fiber reaching the conductive percolation threshold. Although electrical conductivity is 10^6 times lower than metal, it is sufficient to control partial discharge. Disadvantages include high cost and reduced thermal expansion coefficient after carbon fiber addition, with potential cracking if preprocessing is improper.

Technical Features:

- PA66+30CF Organic Polymer Material

- Good Affinity with Epoxy Resin

- 30% Carbon Fiber Conductive Percolation Threshold

- Effective Partial Discharge Control

- Requires Precision Preprocessing Process

Mesh Specifications

Multiple mesh specification options to meet different application requirements

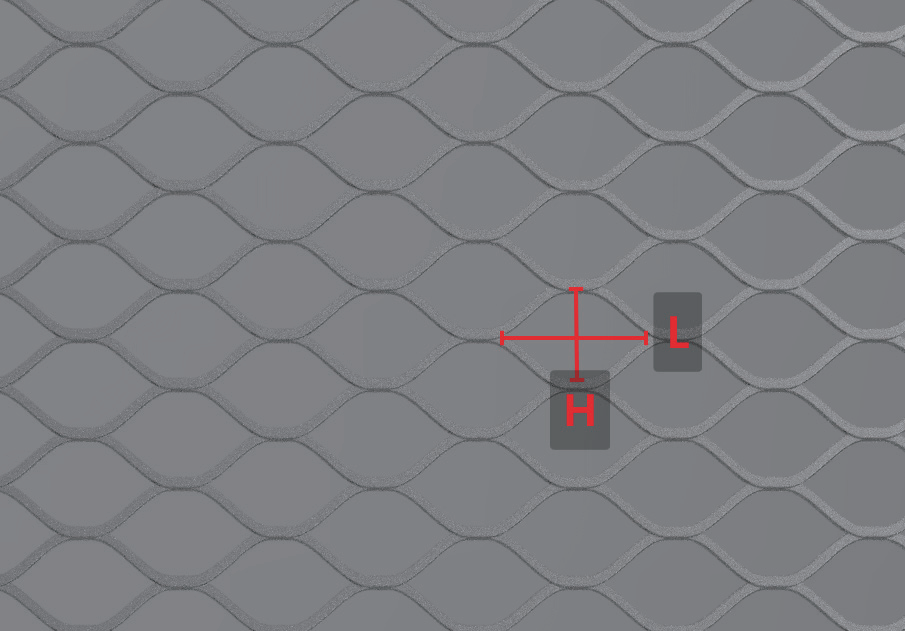

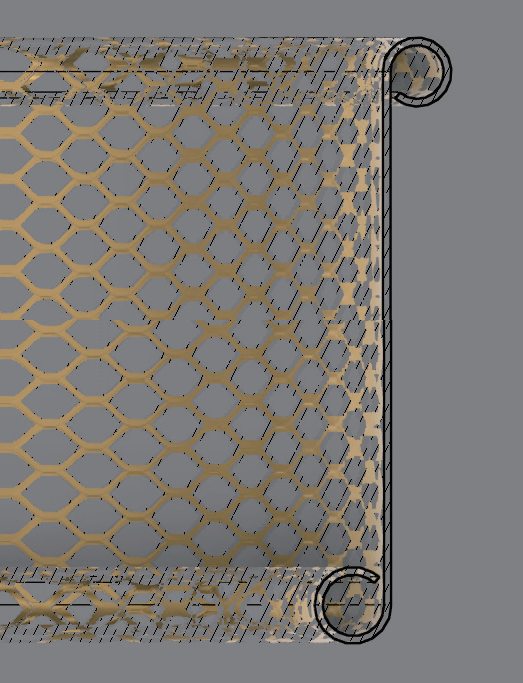

Extended mesh is made by stretching metal plates/strips, featuring high filtration rate and good mesh forming effect. Specifications are indicated by internal H*L dimensions, with shielding nets typically using 2*3 or larger sizes. The disadvantage is high internal stress, which may cause imprecise mesh dimensions and later deformation.

Technical Features

Extended Mesh Structure Diagram

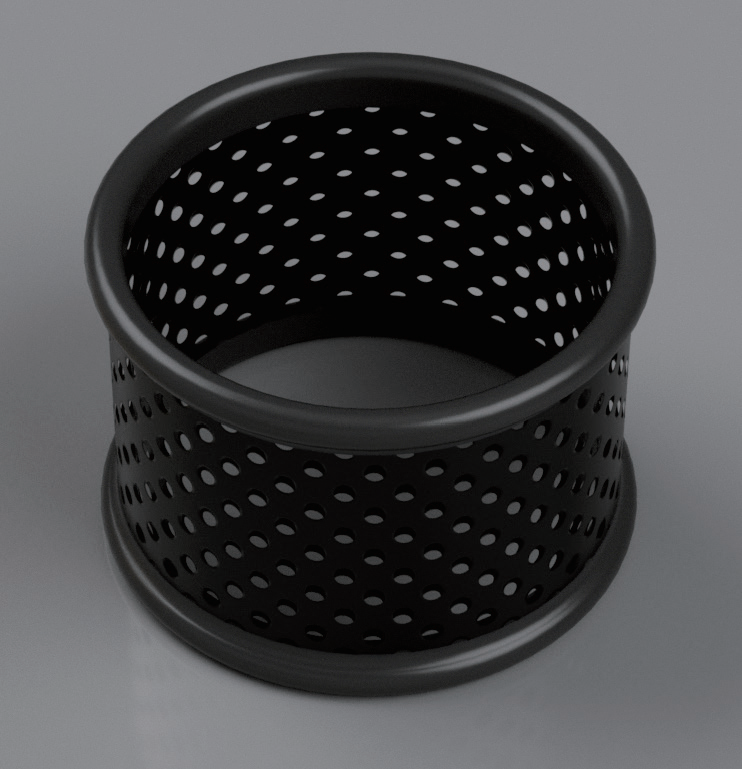

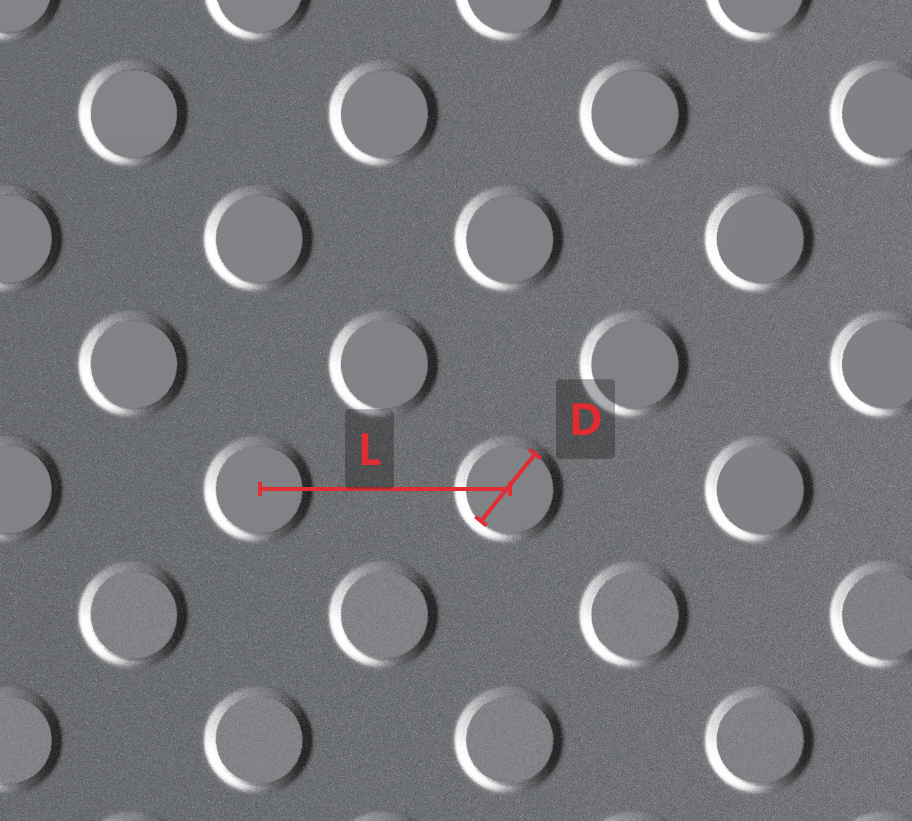

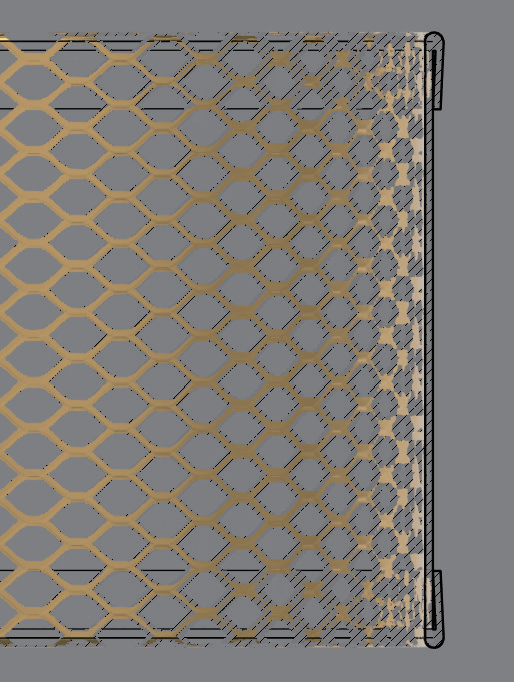

Perforated Mesh Structure Diagram

Perforated mesh is made by punching holes in metal plates. Compared to extended mesh, it has good mesh strength and no internal stress deformation issues, but lower filtration rate. After processing, there are difficult-to-remove burrs inside the holes, so it is rarely used for high-voltage components. Specifications simply indicate diameter and hole spacing.

Technical Features

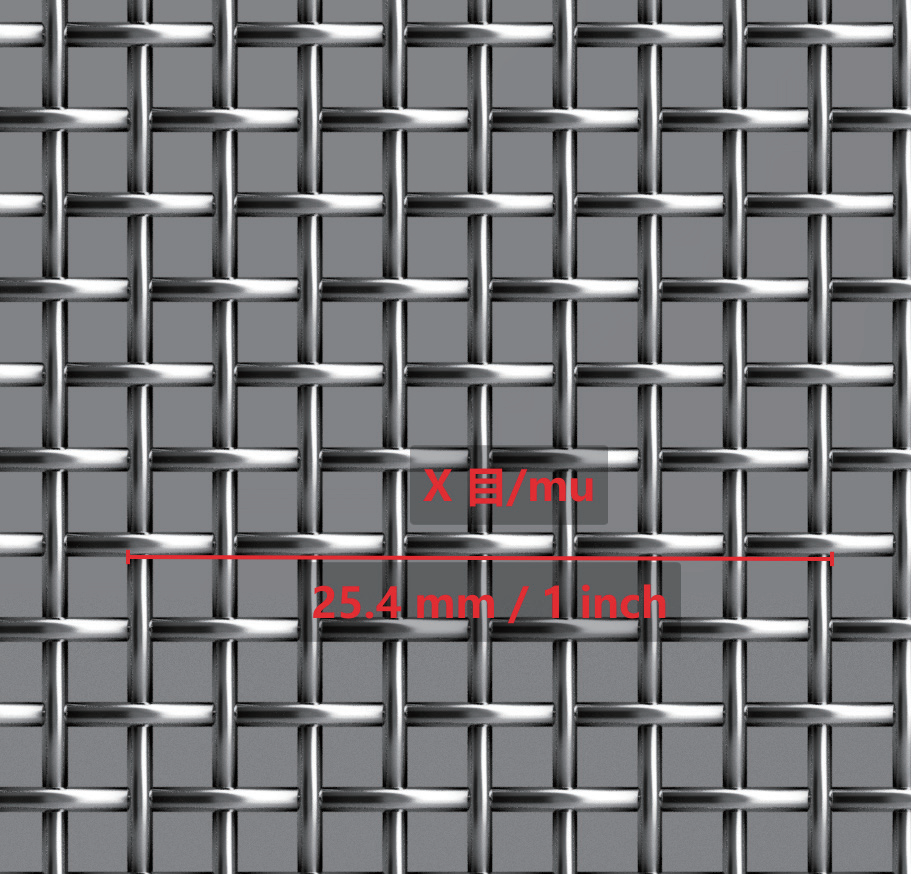

Made by weaving metal wires. Advantages include no burrs and high filtration rate. Disadvantages are poor mesh strength, easy deformation during epoxy casting, affecting insulation distance and partial discharge. Even after edge treatment, mesh wires may still be exposed, so it is rarely used for shielding nets. Specifications are indicated by mesh count (number of holes per 25.4mm).

Technical Features

Woven Mesh Structure Diagram

Processing Techniques

Precision processing techniques ensuring product quality and performance

Curl

Internal and external curling processes ensuring smooth edges without burrs

Fold

Precision folding process improving structural strength and stability

Integrated

Integrated edge design simplifying installation and maintenance

Outer Cone

Outer cone forming process adapting to different installation requirements

Inner Cone

Precision inner cone forming ensuring sealing performance

Hot Forging & Cold Extrusion

Hot forging and cold extrusion processes improving material density and strength

Manufacturing Capabilities

Complete manufacturing system with full-process control from design to finished products

Precision Machining Capabilities

Equipped with advanced CNC equipment, we have comprehensive general machining capabilities for high-precision parts processing and complex shape forming.

- Multi-axis CNC Machining Centers

- Precision Turning and Milling Equipment

- Complex Shape Forming Capabilities

- High Precision Dimension Control

Heat Treatment Processes

Mastering advanced processes such as hot forging and cold extrusion, we can improve material microstructure and enhance product mechanical properties and service life.

- Hot Forging Forming Process

- Cold Extrusion Precision Forming

- Material Microstructure Optimization

- Performance Enhancement Treatment

Inspection and Testing Capabilities

Establishing a comprehensive inspection and testing system, equipped with precision testing equipment such as coordinate measuring machines to ensure product quality meets standard requirements.

- Precision Dimension Inspection

- Material Performance Testing

- Full Process Quality Traceability

Quality Management System

Certified by ISO quality management system, establishing a full-process quality control system from raw material procurement to finished product delivery.

- ISO Quality Management System

- Full Process Quality Control

- Supplier Quality Management

- Continuous Improvement Mechanism